Securing and Safe Lashing

I. Introduction

In today’s global logistics and transportation industry, ensuring the security of cargo is paramount. Securing and safe lashing operations play a vital role in preventing cargo movement during transit, thereby reducing damage risks and enhancing operational efficiency. This article discusses the importance of effective securing and safe lashing, examines the influencing factors, highlights technological innovations, explains practical application methods, addresses common challenges, and explores future development perspectives.

II. The Importance of Securing and Safe Lashing

Cargo security is one of the fundamental aspects of successful logistics operations. Effective securing and safe lashing prevent the load from shifting during transit, even in the face of sudden stops, sharp turns, or adverse weather conditions. This results in:

- Reduced Damage Risks: The cargo is protected from impacts and vibrations that may occur during transit.

- Enhanced Operational Safety: Secured loads ensure vehicle stability and help prevent accidents.

- Cost Savings: Minimizing damage reduces repair and insurance costs.

- Regulatory Compliance: Many national and international transportation standards require adherence to strict lashing procedures to ensure safe cargo handling.

III. Influencing Factors

Several key factors influence the implementation of securing and safe lashing procedures:

- Cargo Type and Characteristics:

- The weight, dimensions, and sensitivity of the cargo determine which lashing methods are appropriate.

- Special cargo, such as fragile or hazardous materials, often requires tailored lashing standards.

- Vehicle and Transport Mode:

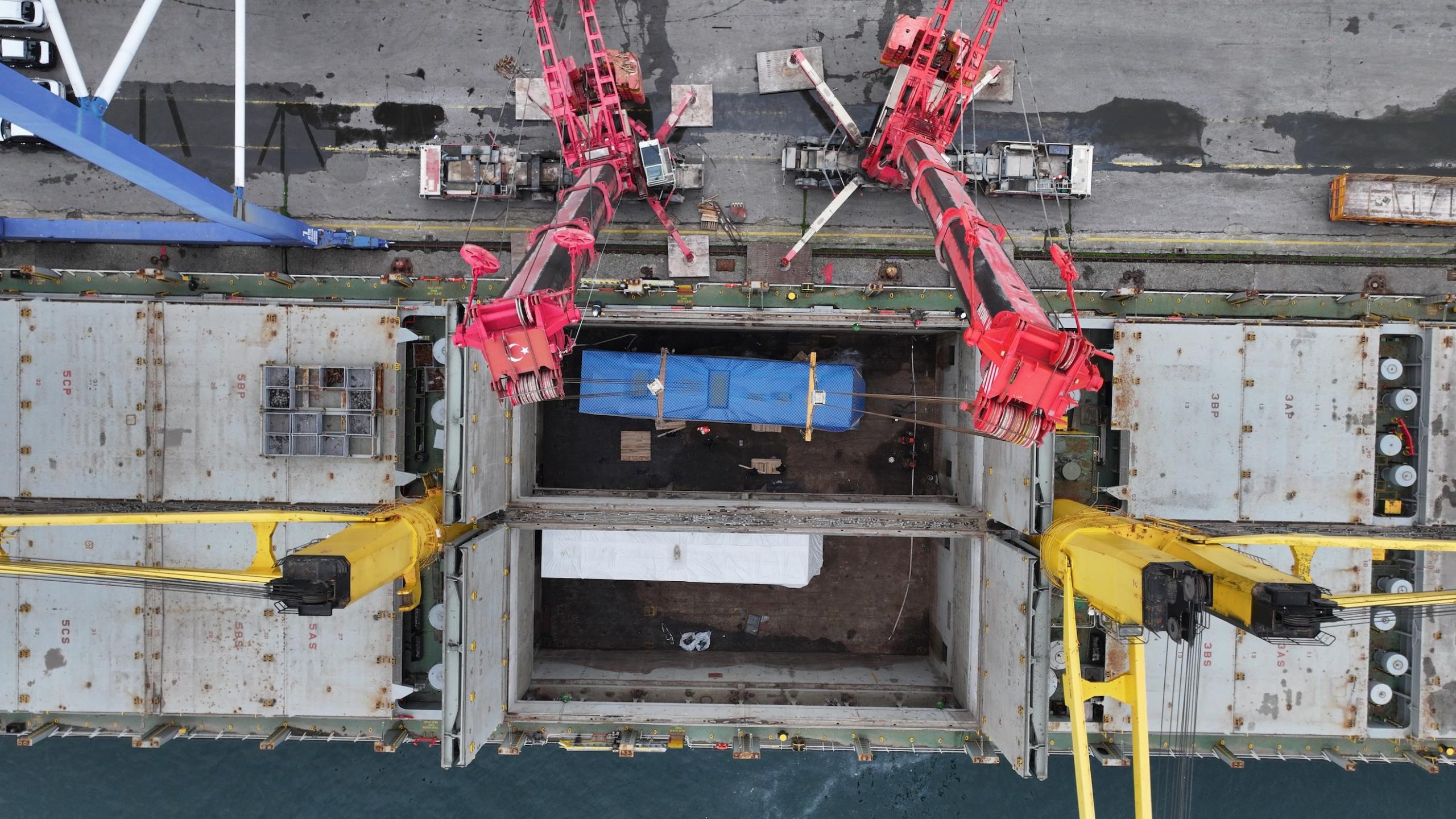

- Different transport modes—road, sea, rail—demand varied securing techniques based on vehicle dynamics and journey conditions.

- Environmental Conditions:

- Weather, road conditions, and journey duration affect the performance and durability of lashing systems.

- Standards and Regulations:

- Adherence to international standards (e.g., ISO, IMO) ensures that lashing operations meet the required safety and quality benchmarks.

IV. Technological Advancements and Innovations

Recent advancements in digitalization and automation have significantly improved securing and safe lashing practices.

- Sensor and Monitoring Systems: Real-time tracking systems enable continuous monitoring of cargo movement, allowing for immediate corrective actions if needed.

- Smart Lashing Systems: Automated tensioning and digital controls reduce human error and enhance the reliability of the lashing process.

- Advancements in Material Science: High-strength synthetic fibers, advanced alloys, and durable connectors have led to the development of long-lasting and highly effective lashing solutions.

V. Techniques and Implementation Methods

Securing and safe lashing can be achieved using various techniques tailored to specific operational needs:

- Traditional Lashing Methods: The use of ropes, chains, and straps has long been established in cargo securing, with each method offering distinct benefits depending on the application.

- Automated Tensioning Systems: Modern vehicles often incorporate systems that automatically adjust the tension of lashing elements to maintain optimal load security.

- Modular Securing Systems: Standardized modules offer flexible solutions that can be quickly configured and reconfigured according to cargo requirements.

- Hybrid Approaches: Combining traditional and automated methods creates robust systems that leverage the strengths of both approaches to maximize safety and efficiency.

VI. Challenges and Proposed Solutions

Despite significant technological progress, challenges in securing and safe lashing persist:

- Human Error: Incorrect lashing techniques or oversight can compromise cargo safety. Regular training and strict adherence to standardized protocols are essential to mitigate these risks.

- Equipment Wear and Tear: Continuous use can lead to the degradation of lashing components. Periodic inspections and maintenance routines help ensure ongoing reliability.

- Environmental Impacts: Extreme temperatures, humidity, and other weather conditions can affect material performance, necessitating the selection of equipment suited to specific environmental conditions.

- Regulatory Compliance: Failing to meet evolving national and international standards can lead to legal repercussions and increased safety risks. Ongoing updates to procedures and equipment are necessary to remain compliant.

VII. Future Outlook

The future of securing and safe lashing is expected to be shaped by further automation, digital integration, and advanced materials.

- Smart Systems: IoT-based monitoring and control systems will provide real-time data on cargo stability, allowing for proactive adjustments.

- Robotic Applications: The integration of robotics in lashing operations will enhance precision and reduce reliance on manual labor.

- Innovative Materials: Developments in nanotechnology and advanced composites are set to yield lighter, stronger, and more durable lashing components.

- Data Analytics and AI: Big data analysis and artificial intelligence will help optimize lashing strategies by predicting optimal methods based on historical and real-time data.

VIII. Conclusion

Effective securing and safe lashing are crucial for ensuring cargo safety, operational efficiency, and cost savings in transportation. By leveraging modern technologies and adhering to robust standards, companies can significantly reduce risks and improve performance. Future advancements in smart systems, robotics, and materials will further enhance the reliability of lashing operations, providing a competitive advantage in the global logistics market.